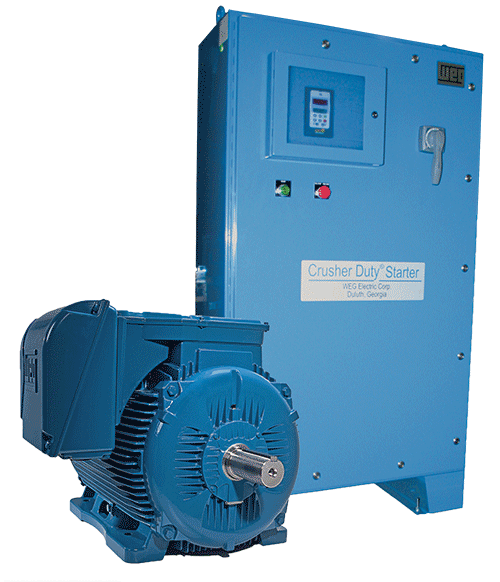

The WEG W22 Crusher Duty motor has been redesigned for even higher performance and energy efficiency, while still retaining all the great features of the previous W21 Crusher Duty motor.

Designed to meet the demanding requirements of the rock crushing industry, the Crusher Duty motor comes standard with 4140 high strength shafts and heavy-duty roller bearings. This motor complies or exceeds EISA 2016 regulations.

Benefits of the new frame design include:

- Motor temperature reduction.

- Eyebolts repositioned – Easier handling in the application.

- Provision for vibration sensors – Frame and endshields with provisions 90-degree displaced according to maintenance technical recommendations.

- Easier and more reliable vibration analysis.

- Solid feet – Enhanced reliability when operating on high vibration applications and also provide easier alignment on installation.

- Oversized Roller Bearings – All WEG Crusher Duty Motors have oversized NU series roller bearings for long life under heavy belt loads.

- Exclusive WSeal bearing sealing system – Extends motor lifetime when operating in aggressive environments by protecting the motor against water and dust guaranteeing proper degree of protection. Frames 586/7 and larger utilize a brass labyrinth Taconite Seal.

- Stator core utilizing C4 coated Low loss Silicon Steel – Premium Electrical Steel for improved efficiency, reliability and repairability, C4 coated silicon steel can withstand burnout oven temperature of 500 C (932 F) minimum, to insure motors can be rebuilt to original performance.